Requirements for Efficient and Secure Processes

Regularly inspecting and maintaining overhead lines is crucial for a reliable energy supply. As technology advances, the use of drones in overhead line inspection is becoming increasingly important. However, specific requirements must be met to ensure or further improve the efficiency and safety of these processes. This article will show how drones can be used sustainably and efficiently for overhead line inspection.

I. Comprehensive Knowledge of Rules and Laws

The successful use of drones in overhead line inspection requires a sound knowledge of the applicable rules and laws, particularly concerning ground infrastructure and drone use. A modern software platform can support this by providing automated functions to check compliance with these regulations. Geographical data is automatically analyzed against current laws and regulations so that potential violations are avoided, and inspections are carried out within legal boundaries. This ensures the safety of employees and third parties and minimizes the risk of potential further restrictions and legal consequences.

The Air Traffic Act, the Air Traffic Regulation, the current implementing regulations and the information for the safe, sustainable and environmentally friendly operation of drones from the European Aviation Safety Agency (EASA) should be known as far as possible.

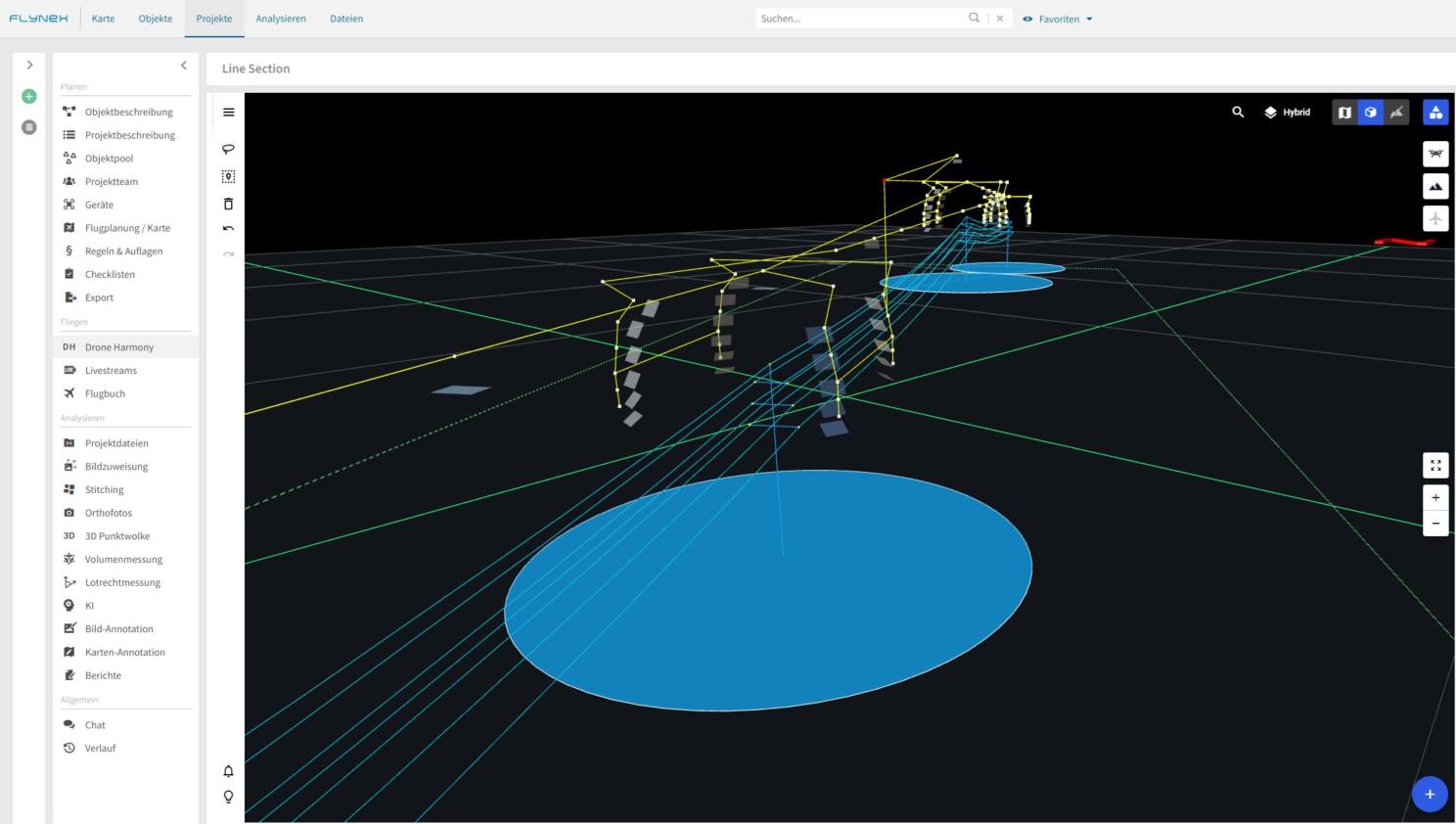

II. Efficient Mission Planning

Precise and efficient planning of overhead line inspections is crucial for successful results. An advanced software platform enables the predictive planning of automated flight routes and the digital transmission of information to field staff. As a result, inspection processes are carried out seamlessly. One office plans and the other carries out the tasks.

A platform should also be flexible enough to adjust flight routes on site, for example, to avoid unexpected obstacles. We have often discovered construction cranes or similar unexpectedly near our mission locations, and the existing flight planning had to be adjusted or discarded. Flexible mission planning increases the effectiveness of inspections and saves valuable time. If the appropriate flight patterns for your objects can also be selected as standard, you don’t need to get creative and complicate the planning.

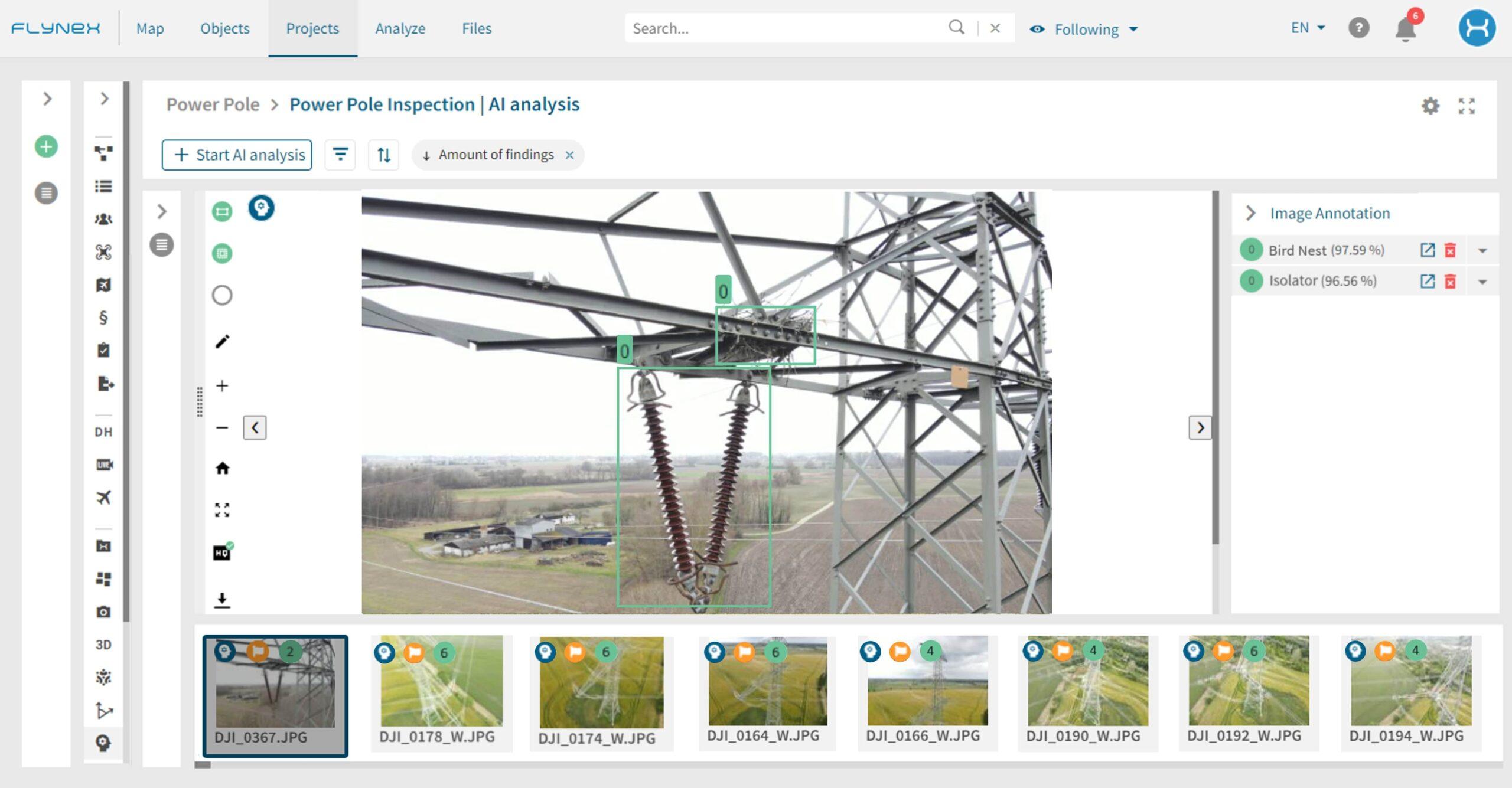

III. Data Analysis With Artificial Intelligence (AI)

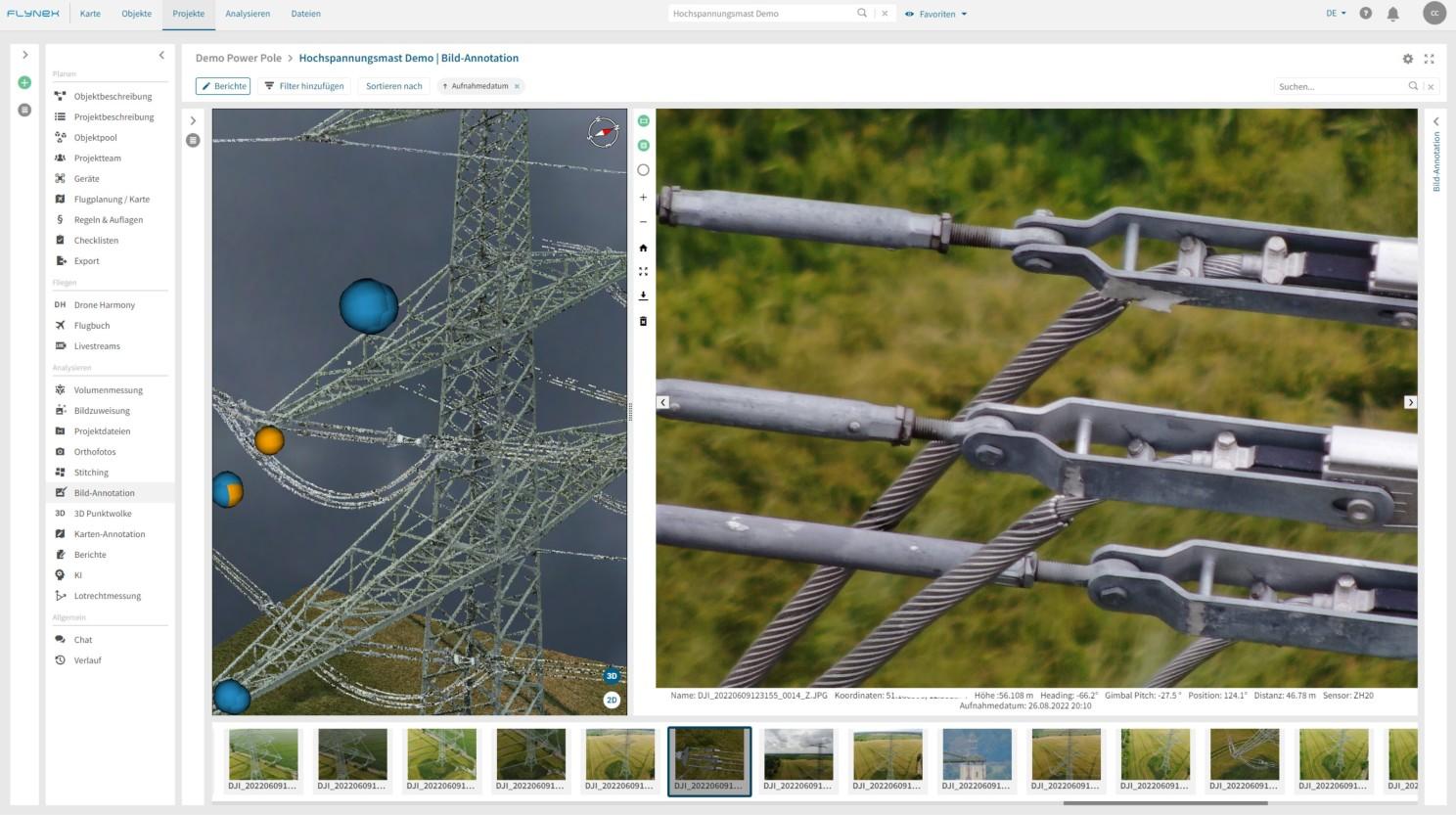

The data collected by drones provides valuable insights into the condition of overhead lines. To analyze this data efficiently and identify potential problems and damage more quickly, using artificial intelligence (AI) has become timely and essential. A modern software platform should be able to integrate powerful AI algorithms that can recognize patterns and deviations. We are talking about cracks, fractures or deformations, for example. Inspection processes can thus be continuously optimized, leading to greater efficiency and better inspection results.

Integrating AI technologies into data analysis thus significantly contributes to ensuring a reliable energy supply. Imagine you could train your own AI for your damage classes; yes, you can.

IV. On-Premise or Cloud Computing Service for Critical Infrastructure?

Data security is of paramount importance during overhead line inspections. For this reason, choosing a software platform that offers an on-premise solution may be advisable. This means that the data and the entire infrastructure are hosted in the company’s own private cloud or data center instead of on external servers or cloud services (Azure, AWS and others). This approach can enable companies to adapt security standards to their specific requirements. The advantages and disadvantages are many and varied and must be carefully considered if a company decides to opt for an on-premise solution. Here are some of the advantages and disadvantages of an on-premise solution.

Advantages of on-premise:

- Maximum control and data security – With state-of-the-art encryption technology and strict access controls, your data can be effectively protected within your own company and under your responsibility

- High availability – Your information is immediately available and enables time-critical decisions and processing at all times

- Specific customizability – A software solution can be adapted more flexibly to the specific requirements of your company so that processes and solutions in your IT infrastructure mesh with one another

Disadvantages of on-premise:

- High costs – In addition to the initial investment costs in your own hardware, there are also costs for software licenses and your own IT infrastructure.

- Responsibilities – All updates and the security of your IT infrastructure are your responsibility and require a specialized team for regular updates to ensure that security gaps are always closed and functions run smoothly

- Further development and updates – When it comes to specific customization for the company, further development of the solution is slower compared to cloud services and significantly more expensive without synergy effects

Conclusion

The time has come to take overhead line inspections to a new level and take full advantage of technological advances. With FlyNex solutions, you can meet the requirements for more efficient and safer processes and successfully meet the future challenges of the energy industry to create a sustainable future for energy supply.

Remember:

1. In conjunction with modern software platforms, drones offer a more efficient alternative to conventional overhead line inspection.

2. The high image quality of drone images enables detailed virtual inspection and artificial intelligence training.

3. Partially automated inspection processes with standardized flight routes facilitate and accelerate inspection work

4. Compliance with legal regulations and permits is mandatory; a software platform can automate the inspection of these regulations.

5. Seek advice from specialists and take advantage of the benefits early on.

Stay tuned to learn more about this topic, and contact us directly if you want to start using these technologies.

Together, we can revolutionize your processes, too!