Prüfung von Bündelabstandhaltern leicht gemacht

Unscheinbare Bauteile mit großer Bedeutung: Bündelabstandhalter. Bei Hochspannungsfreileitungen sind sie mitentscheidend für die Zuverlässigkeit und Sicherheit der Energieübertragung in Freileitungsnetzen. Ohne sie hätten wir ständig mit größeren Stromausfällen zu kämpfen.

Die Kontrolle der Abstandhalter ist sehr aufwendig und wird meist nur bei dringendem Bedarf durchgeführt. FlyNex bietet daher eine zeitsparende und ressourceneffiziente Full-Service-Lösung, die die Sicherheit der Netzinfrastruktur deutlich steigert.

Was sind Bündelabstandhalter?

Bündelabstandhalter dienen dazu, mehrere parallel geführte Einzelleiter eines Bündelleiters in einem definierten Abstand zu halten. Ohne Abstandhalter besteht die Gefahr, dass sich die einzelnen Leitungen z. B. bei Wind berühren, was gravierende Folgen wie großflächige Stromausfälle, Beschädigungen, Spannungsschwankungen, Instabilität, etc. hätte.

Falls die Abstandhalter ihre Funktion also nicht erfüllen können, weil sie fehlerhaft oder beschädigt sind und sich Einzelleiter berühren, ist das Risiko eines flächendeckenden Blackouts sehr groß.

Herausforderungen bei der Prüfung von Feldbündelabstandhaltern

Die regelmäßige Prüfung von Feldbündelabstandhaltern ist eigentlich unerlässlich, da sie für die Stabilität und Leistungsfähigkeit von Freileitungen essenziell sind. Traditionelle Methoden der Sichtprüfung sind aber sehr zeit- und kostenaufwendig. Daher erfolgt die Prüfung vorwiegend nur anlassbezogen.

Dafür kommen z. B. Hubsteiger infrage, um jeden einzelnen Abstandshalter im Detail prüfen zu können. Allerdings bieten nicht alle Trassenabschnitte die idealen Gegebenheiten, um dort mit schwerem Gerät zu arbeiten. Per Helikopter sind Prüfungen ebenfalls möglich, allerdings lassen sich die einzelnen Bündelabstandhalter so sehr viel schlechter sichten und der Aufwand ist sehr hoch.

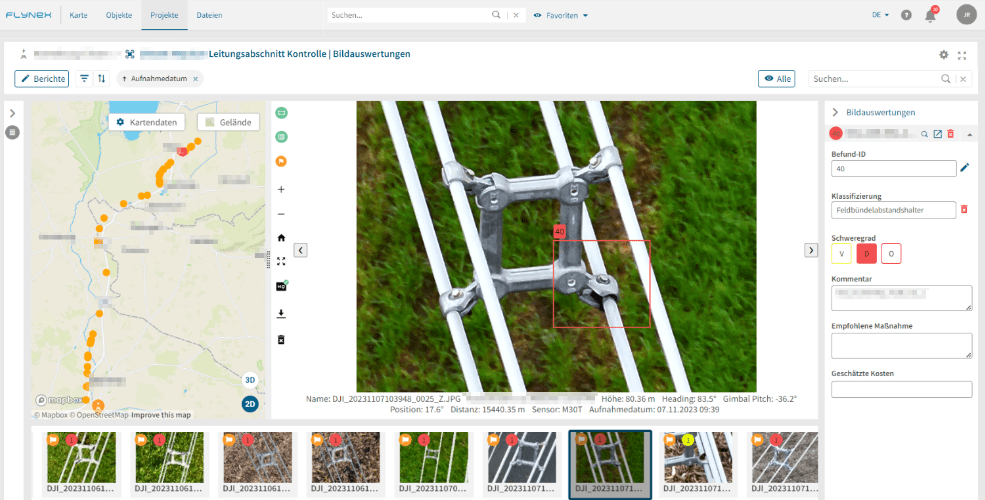

Die FlyNex-Lösung: Drohnenbasierte Inspektion von Bündelabstandhalter

FlyNex setzt für die Prüfung von Feldbündelabstandhaltern auf modernste Drohnentechnologie und einen speziell auf diesen Anwendungsfall abgestimmten und optimierten Prozess. So gewährleisten wir einen effizienten Ablauf und präzise Ergebnisse.

Vorteile der drohnenbasierten Abstandhalterprüfung

- Drohnen können längere Strecken schneller und einfacher abdecken und hochauflösende Bilder aufnehmen.

- Selbst kleinste Defekte und Unregelmäßigkeiten lassen sich auf den Bildern erkennen.

- Die Remote Inspection minimiert das Risiko für das Fachpersonal.

- Deutliche Kosten- und Zeiteinsparungen, da u. a. kein schweres Gerät oder Helikopter benötigt werden.

- Kein Risiko für mögliche Flurschäden durch den Einsatz von Hubsteigern.

- Auch in unebenen oder schwer zugänglichen Gegenden kann eine unkomplizierte und sichere Prüfung erfolgen.

- Die Bilddaten können digital mit Unterstützung von KI effizient und nachvollziehbar ausgewertet werden.

FlyNex hat einen einzigartigen und innovativen Prozess für die präzise Prüfung von Bündelabstandhaltern entwickelt, der bereits praxiserprobt ist und für Kunden umgesetzt wurde. Ein optimiertes Flugmuster sorgt dafür, die Befliegungen möglichst effizient durchzuführen und potenzielle Schäden zu erkennen.

So lassen sich aufwendige Inspektionen umgehen und die Sicherheit der Freileitungen erhöhen.

Fazit

Vermeiden Sie aufwendige und teure Bündelabstandhalterprüfungen! Setzen Sie stattdessen auf innovative und optimierte Prozesse durch den Einsatz von Drohnen und der FlyNex Plattform zur Datenverarbeitung. Steigern Sie die Zuverlässigkeit und Sicherheit Ihrer Freileitungen und prüfen Sie Bündelabstandhalter ab sofort mit FlyNex.

Bei Fragen oder Interesse an weiteren Informationen, nehmen Sie gerne Kontakt mit uns auf.