In der Bundesrepublik gibt es insgesamt über 150.000 Brücken. Diese befinden sich aktuell in einem verbesserungswürdigen Zustand, denn nur etwa 13 Prozent der Brücken erhalten die Zustandsnote „sehr gut“ oder „gut“ und über 10 Prozent von ihnen werden als „nicht ausreichend“ oder „ungenügend“ eingestuft. Dementsprechend hält das Deutsche Institut für Normung zurecht eine regelmäßige Überprüfung der Bauwerke für erforderlich. In der DIN 1076 werden wir zu den rechtlichen Vorgaben fündig: Für sogenannte „Ingenieurbauwerke im Zuge von Straßen und Wegen“ ist alle drei Jahre eine einfache Prüfung und alle sechs Jahre eine umfangreiche Hauptprüfung vorgesehen. Doch die regelmäßige Durchführung von Bauwerksprüfungen ist sehr aufwendig und erfordert meist schweres Gerät und Straßensperrungen. Eine weitaus effizientere Möglichkeit dem steigenden Bedarf an Bauwerksprüfungen nachzukommen, ist die automatisierte Brückenprüfung per Drohne und KI.

Täglich 90 Straßensperrungen für Brückenprüfungen

Täglich werden deutschlandweit rund 90 Brücken durch Fachpersonal geprüft. Werden hierfür herkömmliche Prüfungsverfahren angewendet, ist der Aufwand enorm. Um schwer erreichbare Stellen an den Bauwerken einzusehen, kommen Brückenuntersichtgeräte und Hubsteiger zum Einsatz. Doch das ist noch längst nicht alles: Es sind Einrüstungen der Brücken notwendig, welche wiederum selten ohne Straßensperrungen auskommen. Die Sperrungen müssen nicht nur im Voraus zeitaufwendig beantragt werden, sie führen auch in den meisten Fällen zu Einschränkungen des Verkehrs. In der Folge wird dieser umgeleitet oder kommt sogar ganz zum Erliegen.

Mehr Arbeitssicherheit durch Drohnen

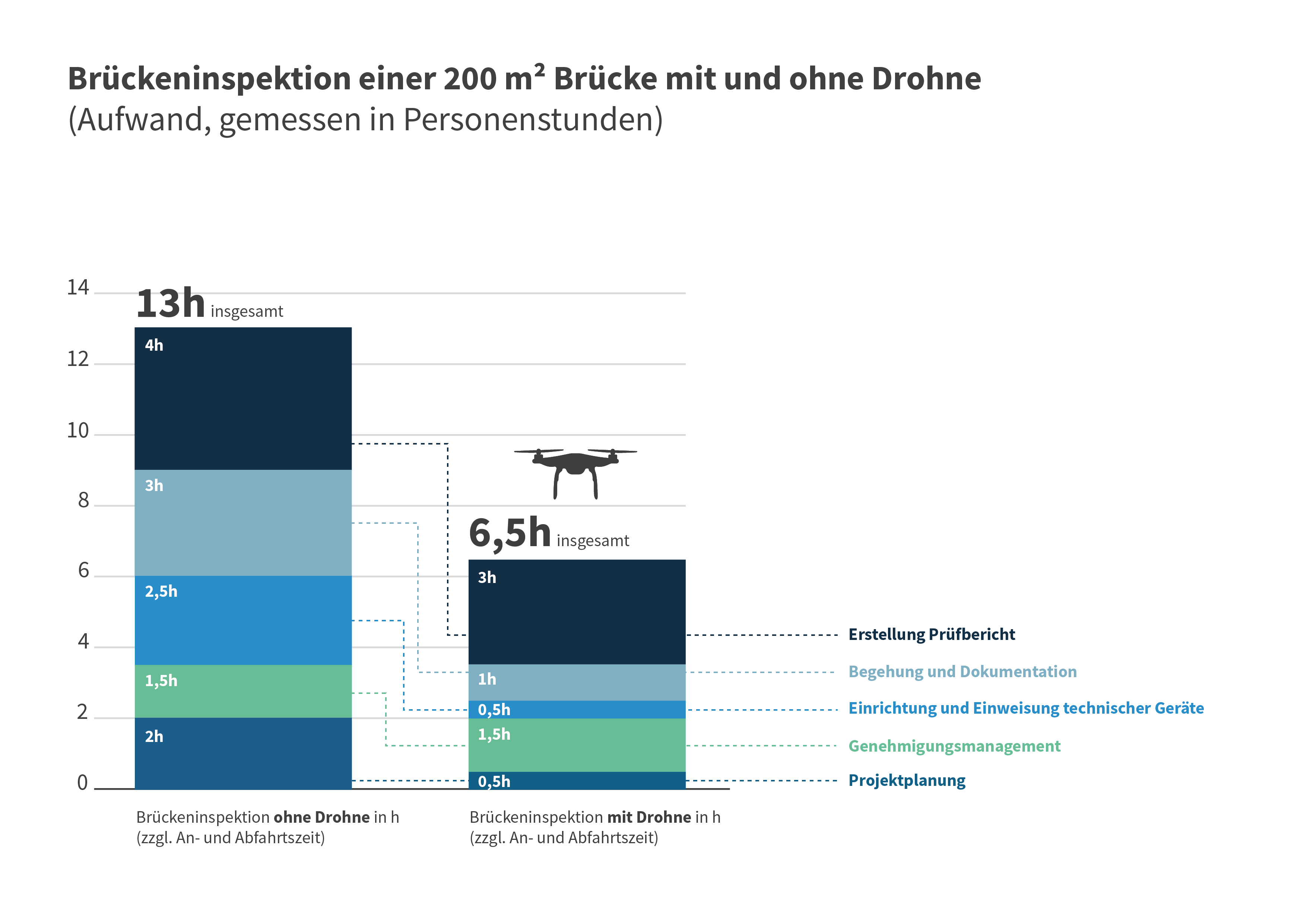

Der Industrieberater GMB prüft seit Jahrzehnten bundesweit Brücken. Dabei veranschlagt das Unternehmen für die Prüfung eines Bauwerks von 200 m² Fläche eine Arbeitszeit von eineinhalb Tagen. Allein fünfeinhalb Stunden hiervon fallen für die Einrichtung und Einweisung technischer Geräte sowie die eigentliche Begehung und Dokumentation an. Zeit, die bei der steigenden Anzahl fälliger Inspektionen und dem allgemein vorherrschenden Fachkräftemangel Zusehens fehlt. Darüber hinaus ist die Gewährleistung von Arbeitssicherheit ein wichtiger Aspekt, der die Notwendigkeit alternativer Techniken zur Bauwerksprüfung unterstreicht. Denn nach wie vor sind Brückenprüfer/-innen bei ihrer Arbeit Sicherheitsrisiken ausgesetzt. Aus diesem Grund sieht GMB den Einsatz von Drohnen und intelligenter Software als Chance zur Steigerung von Prozesseffizienz und Arbeitssicherheit.

Automatisierung per Drohne

Der Lausitzer Industriedienstleister führt deshalb Prüfungen automatisiert aus der Luft durch. Drohnen erreichen selbst schwer zugängliche Stellen, wie Brückenunterseiten, mühelos und kommen ohne schweres Equipment oder Straßensperrungen aus. Drohnenflüge können beliebig oft automatisiert wiederholt werden und sammeln in kürzerer Zeit Daten, die im Anschluss in sehr hoher Qualität vorliegen. Ausgestattet mit der richtigen Sensorik erfassen die unbemannten Flugobjekte selbst kleinste Abplatzungen und Bewuchs. Dies ermöglicht eine zuverlässige Auswertung per Bild-KI, wie zum Beispiel von Viscan Solutions, welche automatisiert selbst kleinste Schäden im Millimeterbereich erkennt.

Durch FlyNex Zeitersparnis von bis zu 50 Prozent

Für die automatisierte Brückenprüfung per Drohne ist die Cloud-basierte FlyNex Enterprise Suite der zentrale Ausgangspunkt. FlyNex bildet das komplette Projektmanagement von der Planung über die Befliegung bis hin zur Analyse ab. Gleichzeitig erfüllt die Software höchste Anforderungen Datenschutz und Datensicherheit.

Der Erfolg spricht für sich: Durch den Einsatz von Drohnen in Verbindung mit der FlyNex Enterprise Software, kann der Zeitaufwand für Bauwerksprüfungen um 50 % reduziert werden.

Falls Sie Fragen zum Use Case Brückenprüfung per Drohne haben, sprechen Sie uns gerne an. Wir freuen uns über jeden Austausch.

Ihr FlyNex Team